Why Should Your Business Invest in Industrial Inkjet Printers?

Selecting the right printing equipment is essential for your business, as it guarantees high-quality output, lowers operational expenses, boosts productivity, and fulfills industry-specific demands, providing you with a competitive advantage.

What are Industrial Inkjet Printers ?

FC PACK offers high-performance industrial inkjet printers specifically designed for heavy-duty use in manufacturing and industrial settings. Utilizing advanced inkjet technology, these printers can print text, images, and barcodes directly onto a wide range of materials such as paper, plastics, metals, glass, and textiles. Known for their speed, precision, and capacity to handle large volumes, our printers are perfect for applications like packaging, labeling, product coding, and marking.

Main Features of Industrial Inkjet Printers from FC PACK :

- High Speed: Capable of printing at speeds between 100-150m/min, ensuring smooth operation on fast-paced production lines.

- Automated Operation: Seamlessly integrates with production lines for continuous, hands-free operation.

- Versatile Code Types: Supports a wide range of code types to meet the diverse needs of various industries.

- Connectivity: Easily connects to computers, PLCs, and other industrial equipment for streamlined integration.

- Data Management: Enables variable data printing and can access databases for dynamic and efficient printing tasks.

- Versatility and Precision: Prints on various materials and surfaces with sharp, clear results, even on small or intricate areas.

Applications of Industrial Inline Printers:

Equipped with advanced features, industrial inline printers are used across various industries, including:

- Packaging: Ideal for printing barcodes, 2D codes, batch numbers, expiration dates, and product details directly on packaging materials.

- Food and Beverage: Ensures compliance with safety regulations by printing expiration dates, batch codes, and product information to maintain product quality and integrity.

- Manufacturing: Marks electronic components, automotive parts, and machinery with serial numbers, logos, and identification marks.

- Pharmaceuticals: Prints critical information such as dosage details, batch numbers, GS1 codes, and expiration dates on medicine bottles, blister packs, and labels.

- Construction: Prints measurements, logos, and safety instructions on construction materials like tiles, bricks, and lumber.

- Promotional and Marketing: Customizes promotional items, banners, signs, and even apparel for marketing campaigns.

The Difference Between Industrial Inkjet Printers and Other Printers

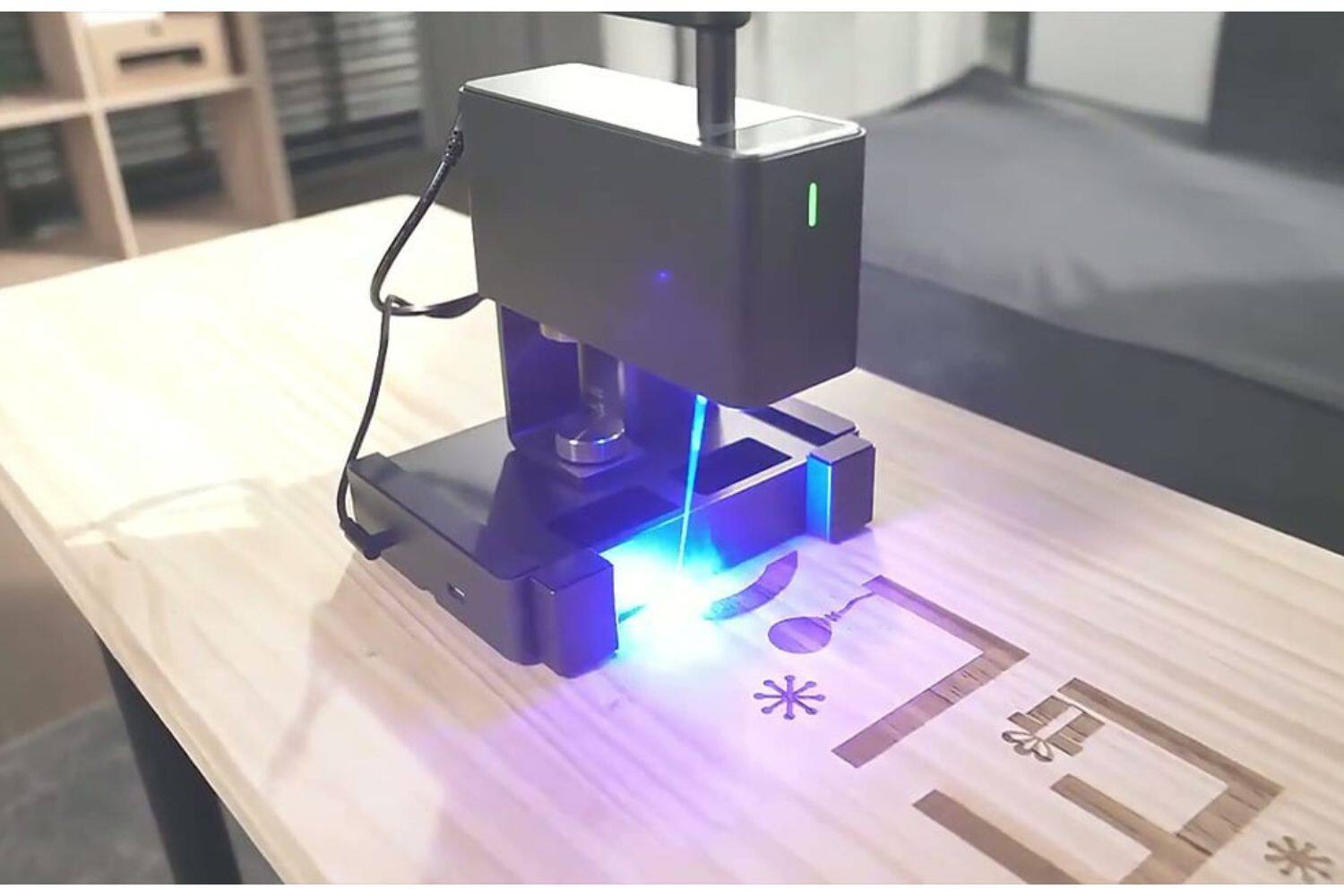

Industrial Inkjet Printers VS Industrial Laser Printers

When selecting between industrial inkjet printers and industrial laser printers, it is essential to recognize their unique features, benefits, and limitations. Each technology offers distinct advantages based on specific applications and operational requirements. Here’s a concise comparison of these two types of industrial printers.

Industrial Inkjet Printer Pros and Cons

Industrial inkjet printers use liquid ink ejected from nozzles to create images and text on various substrates. They are recognized for their versatility and adaptability in diverse industrial environments.

Pros

- Versatility: Capable of printing on a wide range of materials, including metals, plastics, and glass, making them ideal for applications that require high flexibility in substrate choice.

- High-Speed Printing: Designed for high-speed, high-volume printing with continuous operation, suitable for large-scale production environments.

- Variable Data Printing: Ideal for printing unique codes, serial numbers, and batch information on each item.

Cons

- Ink Costs: Consumable ink can be expensive, leading to higher costs with high-volume printing.

- Maintenance: Requires regular maintenance to prevent clogging and ensure consistent print quality.

- Durability of Prints: Inkjet prints may be less durable compared to laser prints, especially in harsh conditions.

Industrial Laser Printers Pros and Cons

Industrial laser printers utilize focused laser beams to etch or mark text and images onto various substrates. They are known for their precision and durability.

Pros

- Durability: Produces highly durable and permanent marks that resist abrasion, chemicals, and high temperatures.

- Low Operating Costs: No need for consumables like ink or toner, reducing long-term operating costs.

- Precision: Extremely precise, suitable for fine details and small text.

Cons

- Material Limitations: Best suited for specific materials, such as metals and certain plastics; not as versatile as inkjet printers in terms of material compatibility.

- Higher Upfront Cost: Generally more expensive to purchase and set up.

- Lower Speed: Often takes more time to complete marking and engraving tasks.

Application Scenario Comparison

| Industrial Inkjet Printer | Industrial Laser Printer |

|---|---|

| Product coding and marking on various materials | Engraving and etching on metals and ceramics |

| Label expiry dates on packaging | High-precision marking on electronic components |

| Printing high-quality and scannable barcodes | Creating permanent, durable marks for compliance |

| Marking logos and promotional information | High-speed marking for serial numbers and QR codes |

Choosing between industrial inkjet and laser printers depends on your business’s specific needs. Inkjet printers offer versatility and high-quality printing, making them suitable for a broad range of materials and applications. Laser printers provide durability and precision, ideal for high-speed marking on specific materials. Understanding the strengths and limitations of each technology will help you make an informed decision aligned with your production requirements.

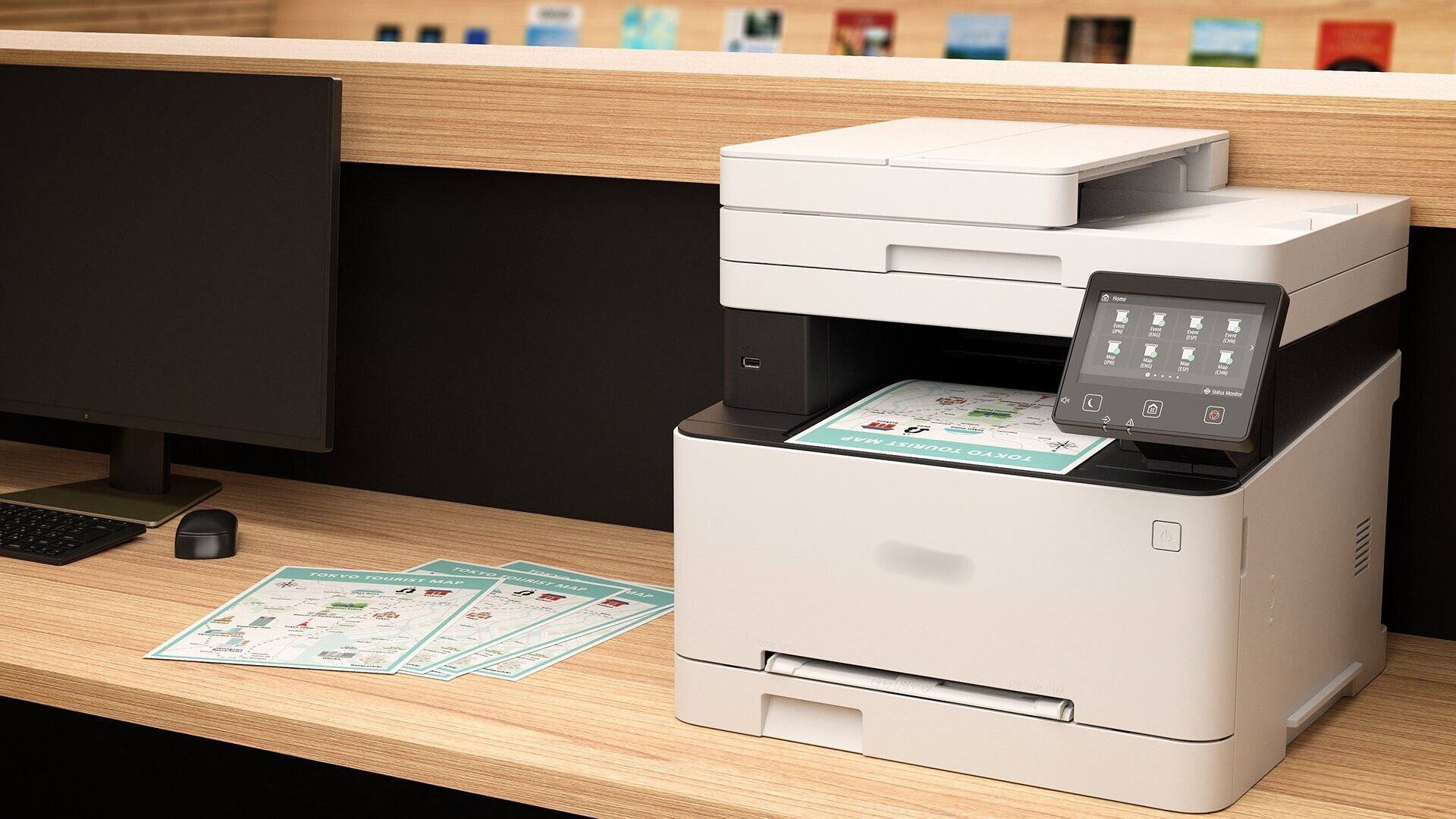

Industrial Inkjet Printers vs. Typical Printers

Typical printers, often referred to as office or consumer printers, are designed for general-purpose use in home or office environments, focusing on reliable, cost-effective printing for documents, photos, and occasional labels.

Pros

- Cost-Effective: Typically have lower upfront costs and are more affordable for everyday printing needs. Ink and toner cartridges are usually less expensive compared to industrial printer consumables.

- User-Friendly: Generally easy to use with straightforward interfaces, suitable for non-specialized tasks in home and office settings.

- Compact Design: Designed for smaller workspaces, making them easy to integrate into office environments.

Cons

- Limited Material Handling: Primarily designed for printing on standard paper and common office materials; not suited for industrial-grade substrates.

- Lower Speed and Volume: Not designed for high-speed or high-volume printing; may struggle with continuous, large-scale tasks.

- Durability and Reliability: Generally not built for high-demand environments, potentially leading to issues with print quality and reliability under heavy use.

Comparison between Industrial Inkjet Printer and Typical Printer

| Compare Features | Industrial Inkjet Printer | Typical Printer |

|---|---|---|

| Application Suitability | Best suited for environments requiring flexibility and high-resolution prints, such as packaging and product labeling. | Ideal for office or home use, limited to document and photo printing on standard paper; not suitable for industrial applications. |

| Cost Efficiency | Higher ongoing ink costs, but suitable for diverse substrates and continuous high-speed printing. | Lower initial costs, but ink or toner consumables can also be costly. |

In conclusion, industrial inkjet printers and typical printers serve distinct roles. Industrial inkjet printers offer versatility, high-speed performance, and high resolution for industrial needs. In contrast, typical printers are cost-effective, user-friendly, and ideal for general office or home use. Recognizing these differences helps in choosing the right printer for specific requirements.

5 Business Benefits of Using Industrial Inkjet Printers

Simpler and More Efficient Workflow:

Industrial inkjet printers seamlessly integrate into production lines, automating high-speed, high-volume printing and reducing manual intervention. This streamlines operations, accelerates processing, and minimizes bottlenecks.Data Management Capabilities:

These printers support variable data printing and database integration, facilitating the management of unique codes, serial numbers, batch information, images, and other dynamic data, enhancing traceability and compliance.Diverse Code Types:

Industrial inkjet printers can print a wide range of codes, including 1D barcodes (UPC, EAN, Code 39, Code 128, etc.), 2D barcodes (QR, Data Matrix, GridMatrix, GS1DM, PDF417), as well as batch codes, expiration and manufacturing dates, and customized alphanumeric codes, providing flexibility for various industrial applications.High Resolution and High-Speed Printing:

With resolutions up to 2,400 DPI, industrial inkjet printers produce sharp, clear images and text at high speeds, ensuring efficient production of large volumes with precise detail and improving overall product quality.Versatility in Surface Printing:

These printers can print on a variety of substrates, including carton, plastic, metal, and glass. Their specialized inks adhere well to different surfaces and dry quickly, making them suitable for diverse business environments.